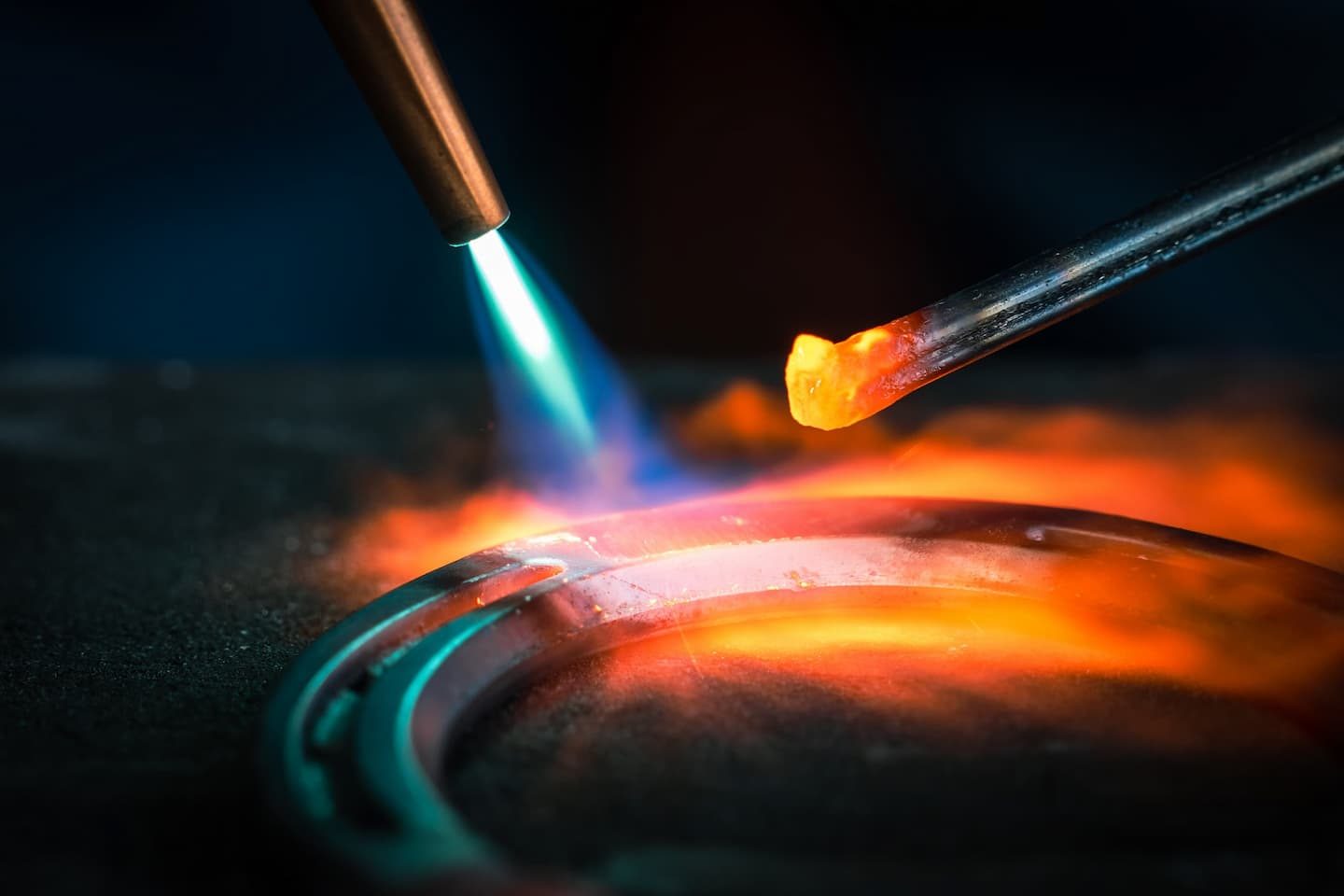

Tungsten Tube Metals & Tungsten Carbide Grit for Welding

Tungsten carbide grit provides long lasting wear protection in areas of high abrasive wear. Tungsten carbide grit is an efficient means of protecting machinery and machinery parts by providing a significant increase in the longevity of those parts. This decreases downtime and reduces the cost involved with unprotected parts.

Look Through Our Selection of Tungsten Tube Metals & Welding Grits

Our Tungsten Carbide Grit is screened to meet a variety of different specifications and sizing requirements. The crushed tungsten is made of sintered tungsten carbide with a cobalt binder for welding applications. During the application process, the crushed tungsten particles are delivered to a molten weld pool at precisely the right moment prior to the puddle freezing. The result is a weld deposit filled with tungsten carbide surrounded in a tool steel matrix.

Tungsten Tube Metal

Tubemetal – crushed sintered/cast tungsten particles wrapped in a sheath of weldable alloy steel. OD Sizes range from 1/8″ diameter to 1/4″ diameter, 14 to 28 inches in length. Our standard alloy blend was developed over the years to give you the maximum efficiency and wear resistance from our tubemetal.

- Acetylene Tubemetal

- Electric Tubemetal

- Horse Shoe Tubemetal

- Acetylene Sintered

Brazing rod with tungsten carbide grit in a wear-resistant metal matrix. This product should be applied with a torch.

Brazing rod with tungsten carbide grit in a wear-resistant metal matrix. This product should be applied with a torch.

Horseshoe brazing rod with tungsten carbide grit in a wear-resistant metal matrix. This product should be applied with a torch.

Brazing rod with tungsten carbide grit in a wear-resistant metal matrix. This product should be applied with a torch.

Tungsten Carbide Welding Grits

Tungsten carbide particles dispersed into a molten weld metal matrix to form a highly

wear resistant deposit, especially suited for ground engagement tools. We recommend

Rankin’s tough iron base or nickel base wire for the matrix wire.

Tungsten Tube Metal Applications

Tungchip Tube Metal can be used in the following fields: sand, grit, stone and cement industries, coal and stone mining, ore-mining, road building, brick fabrication, drilling, construction, lime and ceramic industry and mining machinery.

Cutting blades, scrapers, slag breakers, all forms of screws, grinders, cutting bits, mixing shafts, cylinder parts, shock plates, grading knives, plough shares, core bits, guide rollers, fishtail parts, drills, cutting heads, elevator brakes, edge scrapers, mixing blades, mill hammers, etc.

Tungsten Brazing Grit Applications

Typical equipment that can benefit are mining and construction equipment, dredging equipment, mixing, blending, shredding and processing equipment, drill bit equipment and agricultural parts.

Welding Tips

-

Base metal

Tungchip Tube Metal is suitable for use with all non-alloyed and base alloyed steels or cast steel products with a carbon ratio of up to 0,5%. If the carbon content is above this level, bonding difficulties may occur and a reduction in impact resistance can occur.

-

Application

Tungchip Tube Metal is oxyacetylene welded so preliminary heating of the separate components is unnecessary. Choose a welding torch a size or two smaller than is used for ordinary joint welding. The flame should be adjusted to neutral as illustrated in Figure 3.

-

Preparation of material

Ensure that all surfaces are free from rust, scale, grease and other impurities. The process works best on surfaces which have been cleaned through mechanical processing or grinding, ensuring a satisfactory bonding of the alloy.

Protect Your Equipment

with Our Tungsten Tube

Metals & Welding Grits

Have questions regardign pricing or looking for other information? Contact us today!

Give us a call at 281-426-5535 or click the button below